Quality Assurance in Bloodbag Production

Manufacturing Processes and Protocols

Ensuring the safety of blood bags is crucial for maintaining the quality and reliability of blood transfusions. The procedures and guidelines followed during the production of blood bags are carefully crafted to meet safety criteria. This involves selecting materials with care and precision. The components utilized in blood bag manufacturing must be compatible, with the body’s biology and devoid of impurities to avoid any negative effects when transfusing blood. Manufacturers commonly use notch medical grade materials that have been extensively tested for safety purposes.

Sterilization methods are essential for keeping blood bags free from contaminants and bacteria infestation risks while maintaining their integrity intact before being delivered to healthcare professionals.

To maintain standards of quality control throughout the production process is crucial. These steps involve testing to check for leaks and ensure strength and durability in different situations. Every set of blood bags undergoes scrutiny to ensure they meet the established quality criteria before being cleared for distribution.

Testing Procedures for Bloodbags

It is crucial to conduct tests to confirm that blood bags meet safety standards effectively. The testing process includes replicating real-life scenarios to evaluate the functionality of the blood bags. Various tests are conducted, such as pressure assessments to detect leaks and tensile strength evaluations for durability checks. Compatibility trials with various anticoagulants commonly used in storage are performed.

Challenges in Maintaining Bloodbag Safety Standards

Common Issues in Bloodbag Production

With rigorous guidelines in place for blood bag manufacturing processes, there are typical challenges that arise in the production process. An example of such a challenge includes the variation in material quality caused by fluctuations in supplier dependability or alterations in the sources of materials. These fluctuations can result in irregularities in how the product functions.

Addressing Contamination Risks

The risk of contamination is a worry when making blood bags, so it’s super important to keep everything sterile during production to avoid any germs that could harm patients’ safety. To tackle this problem, using high-tech sterilization methods and keeping the manufacturing environment clean really helps minimize these risks effectively.

Technological Advancements and Their Impact

Over the years, advancements in technology have significantly improved the safety standards of blood bags. Innovative methods like automated manufacturing have helped minimize errors and ensure production. Furthermore, progress in material science has resulted in the creation of more dependable materials for blood bags.

Moreover, modern digital monitoring systems have the capability to monitor every stage of the production process in time. This enables analysis to detect and address potential problems before they impact the quality of the final product. Such a proactive method helps in rectifying any deviations from established procedures.

Integrating these upgrades doesn’t just boost the safety and dependability of blood bags but also enhances efficiency in manufacturing plants. A win-win for both producers and healthcare providers.

To sum up, the importance of ensuring the quality and reliability of blood bags lies in upholding safety standards throughout the manufacturing process and testing phases while embracing technological advancements to meet challenges and prioritize patient well-being effectively.

The Role of Healthcare Professionals in Ensuring Safety

Training and Education on Bloodbag Handling

Healthcare providers have a role in upholding safety standards for blood bags to ensure patient well being and prevent contamination risks through proper handling and storage practices. Training and education are key to equipping medical professionals with the necessary knowledge of blood bag protocols, including techniques for collection and storage as well as transfusion procedures, which are commonly covered in training programs with detailed instructions.

Education also includes recognizing the significance of utilizing top notch blood bags that adhere to safety protocols. By familiarizing themselves with the manufacturing procedures and quality assurance steps associated with blood bag production, medical professionals can make informed choices when choosing supplies for their healthcare settings.

Monitoring and Reporting Adverse Events

Healthcare workers also have a role in overseeing and documenting any negative occurrences associated with the use of blood bags, like tracking instances of pollution or leakage that could jeopardize patient well-being. This proactive reporting by healthcare providers plays a key part in a cycle of feedback where manufacturers can enhance their products and tackle possible hazards early on.

The use of monitoring systems can help in this regard by analyzing real-time data on the performance of blood bags efficiently and effectively for healthcare professionals to promptly address any unexpected issues that may arise and take appropriate actions.

Medco’s Commitment to Excellence in Bloodbag Production

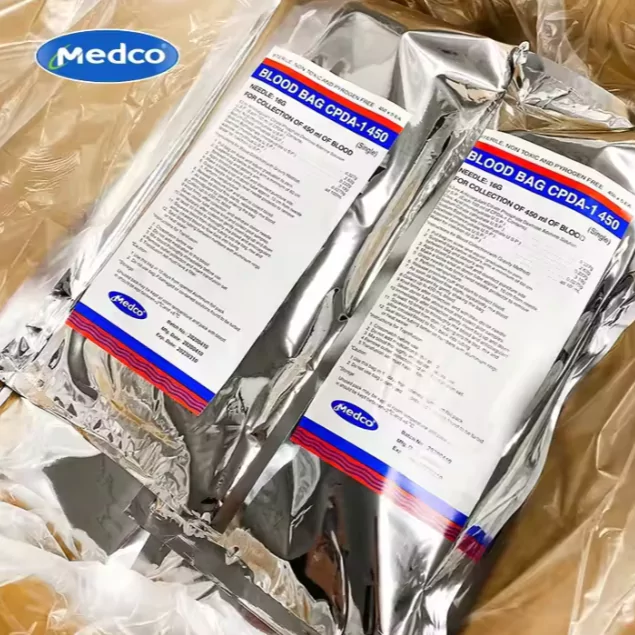

Medco’s Commitment to Excellence in Bloodbag Production

Medco Health Care Co., Ltd., a respected medical devices provider that specializes in medical equipment in China and is known for producing top notch diagnostic instruments, disposable medical supplies and laboratory supplies meeting industry standards and undergoing thorough testing procedures before being sent out for distribution.

Medcos manufacturing plants follow safety protocols and use sophisticated machinery for accurate production processes. The company holds certification from CE0123 & ISO13485 as well as FDA approval to demonstrate their adherence to safety standards.

Medco Health Care Co., Ltd. through upholding quality assurance measures and utilizing the latest technological innovations in the industry remains at the forefront of providing trustworthy blood bags that cater to healthcare providers worldwide’s requirements effectively and safely. Their proactive stance guarantees manufacturers and healthcare practitioners alike can depend on their products with confidence, for delivering efficient patient care.