Sustainability is becoming a vital element of ethical company practices, not only a catchphrase. Effective waste management techniques help many businesses reach their sustainability objectives. Adopting an industrial cardboard baler can help simplify recycling initiatives with a straightforward yet efficient approach. These machines let companies easily accomplish their environmental goals, lower trash volume and increase recycling efficiency. Investing in an industrial cardboard baler could be the game-changer your business needs if it is seeking a reasonably priced and sensible approach to improve sustainability.

Growing Demand for Corporate Sustainability

Companies have to give sustainability a priority as consumer demand for environmentally friendly firms rises along with environmental laws. The corporate environmental effect is highly influenced by waste management, hence one of the main issues businesses deal with is too much cardboard trash. Whether you run a distribution center, manufacturing plant, or retail store, cardboard waste may gather rapidly. Using a baler-based organized recycling program will help greatly lower landfill contributions and enhance general waste management.

Describe an Industrial Cardboard Baler

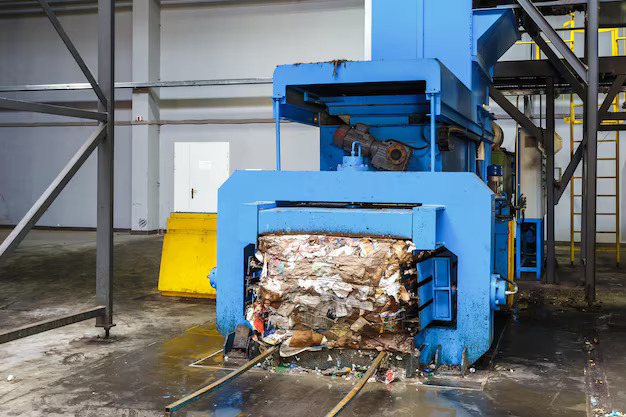

An industrial cardboard baler is a machine meant to compress and bind big amounts of cardboard into small bales, therefore facilitating the storage and transportation of recyclable products for businesses. Both small businesses and big companies will find these balers in different capacities and sizes. Compacting cardboard waste helps businesses save storage space, save waste hauling costs, and boost recycling program efficiency.

Advantages of an Industrial Cardboard Baler

1. Waste Disposal Cost Savings

Reducing trash disposal expenses is one of the instant advantages of using a cardboard baler. Smaller space occupied by compacted bales allows companies to reduce the frequency of waste collecting services, therefore saving waste removal costs.

2. Enhanced Recycling Effectiveness

Loose cardboard sorting and disposal can take time and be ineffective. By compressing items into reasonable bales, a baler streamlines this procedure and lets companies recycle more effectively and follow environmental rules more faithfully.

3. Space Saving Strategies

A messy workplace can lower output and generate safety risks. By removing mounds of loose cardboard, balers save precious floor space and improve the organization and hazard-free nature of the workplace.

4. Environmental Advantage

By lowering landfill waste and encouraging recycling, using a cardboard baler greatly helps attempts at sustainability. Companies that aggressively recycle their cardboard products promote a circular economy, help to save resources and reduce carbon footprints.

Selecting a Cardboard Baler for Your Company

Your company’s volume of cardboard waste, available space, and operational requirements will determine which baler is best. Among the important considerations are:

Baler Size and Capacity: Large-scale companies could need vertical or horizontal balers with high compression power, while smaller companies might gain from compact balers.

Ease of Use: Look for balers with automatic functions and easy-to-use controls to expedite processes.

Durability and Reliability: A premium baler constructed of robust materials will guarantee a lifetime and demand less regular maintenance.

Cost and ROI: Think about the baler’s initial outlay against long-term waste management savings.

Establishing a Cardboard Recycling Program

Once you have a baler, it is imperative to create a recycling plan that makes the best use of it. In this manner:

1. Teach Workers Correct Baling Techniques

- Staff members should be confident they can effectively and safely run the baler.

- Simplify and make the procedure easy to inspire consistent recycling practices.

2. Set Up a Collection System

- Before the baler runs through, set aside particular spaces for cardboard collecting.

- Sort recyclables from non-recyclables in well-labeled bins.

3. Partner with Recycling Companies

- Work with nearby recycling centers to guarantee effective baled cardboard pickup and processing.

- Certain recycling businesses might even provide incentives for premium, well-balanced materials.

4. Monitor and Adjust as Needed

- Evaluate the effectiveness of your recycling program often and change depending on the demands of your company.

- Maintaining current with industry trends and best practices can help to maximize initiatives towards sustainability.

Keeping Your Baler In Use Over Long-Term

Regular maintenance is crucial to guarantee your baler runs for years and is effective. Good maintenance can help avoid expensive failures and maintain the equipment in the best working order.

- Plan routine inspections for wear and tear on important parts like hydraulic systems and electrical controls.

- Regular cleaning of the machine helps to prevent the accumulation of cardboard residue, dust, and trash that could compromise performance.

- Replace Worn-Out Parts: To keep efficiency over time some parts could need replacement.

The Value of Baler Parts and Maintenance Services

Even the toughest balers will call for sporadic maintenance and part replacements. Minimal downtime and best machine performance depend on working with a trustworthy baler parts and repair vendor. Professional repair services and high-quality replacement components will help your baler last longer, therefore maintaining seamless recycling operations and economy of cost.

Summary

One does not have to find great difficulty in meeting sustainability targets. Using an industrial cardboard baler in your recycling operation is an easy but effective way for companies to lower waste, save money, and improve the surroundings. Your business may greatly advance sustainability by selecting the correct baler, keeping it in good condition, and guaranteeing effective recycling policies, therefore enhancing operational effectiveness. Now is the moment to get a baler and take charge of your company’s recycling plan if you’re having trouble handling cardboard waste.