The API 610 standard plays a role in the pump industry with a focus on centrifugal pumps utilized in sectors such as petroleum refining and natural gas processing facilities.The standard sets out requirements for design quality and performance to ensure that pumps can operate effectively under challenging conditions common in these industries.This adherence to standards allows manufacturers to create pumps that’re both efficient and durable, in demanding environments.

Definition and Purpose of API 610

The API 610 standard sets out the specifications and criteria for pumps utilized in the oil and gas industry to ensure their efficient operation in diverse conditions, like high pressure and temperature settings The guidelines encompass design parameters material choices testing protocols and documentation needs By adhering to the standards set forth in API 610 guidelines,such as those followed by manufacturers such, as Yantai Longgang Pump Industry Co., Ltd. who manufacture a range of centrifugal pumps including BB series,OHand VS series pumps can be confident that their products meet globally recognized quality standards.

Historical Development of API 610 Standards

The API 610 standard has evolved over time to meet the evolving needs of the industry by providing a framework for pump manufacturers and incorporating technological advancements and industry feedback through revisions aimed at improving pump performance and reliability while maintaining safety standards compliance. Yantai Longgang Pump Industry Co., Ltd. a company acknowledged as a “high tech enterprise” and playing a role in establishing standards, for the pump industry is actively contributing to this continuous evolution process.

Key Components and Specifications in API 610

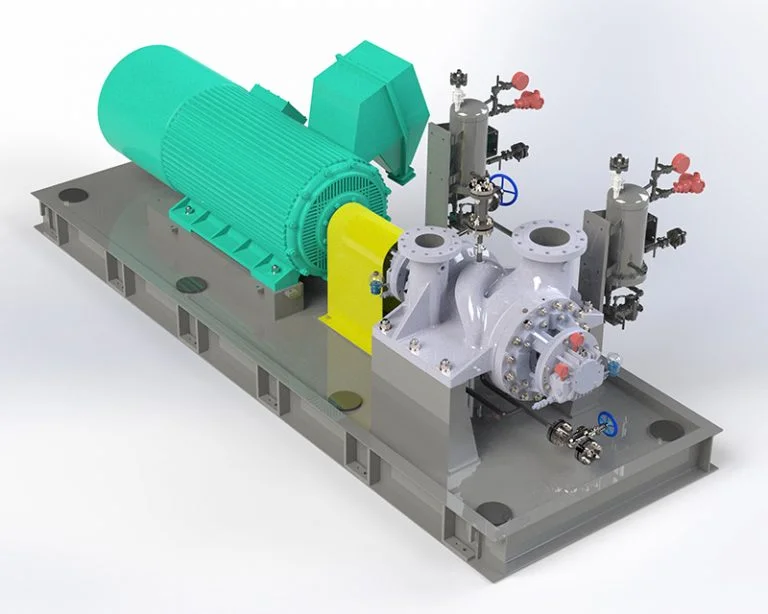

The API 610 standard lays out requirements and details that pumps need to follow carefully.These consist of design elements like split casing double suction impellers,sturdy shaft designs and robust bearings.For instance Yantai Longgang’s BB1(LAD)pump range showcases a split casing with a double suction impeller arrangement crafted in line, with API guidelines.These specificities guarantee that pumps can effectively manage pressure and corrosive substances.

How Do API 610 Standards Improve Pump Reliability?

Following the guidelines set by API 610 greatly improves the reliability of pumps as it ensures their strength and minimizes the need, for frequent maintenance tasks thereby offering a solid foundation for manufacturers to create durable pumps that can withstand challenging working environments.

Role of API 610 in Ensuring Mechanical Integrity

The durability and performance of pumps heavily rely on their integrity to ensure they last long and work efficiently over time.The API 610 standard is instrumental in setting design requirements that boost longevity.For example the inclusion of bearings with extended lifespan helps reduce noise and vibrations while the incorporation of double suction impellers, for self balancing axial forces supports steady pump functioning.

Impact on Maintenance and Downtime Reduction

Adhering to API 610 guidelines not guarantees the structural soundness but also has a notable effect on maintenance timetables and minimizing downtime issues. Pumps fashioned in line with these regulations necessitate frequent upkeep thanks, to their sturdy build and dependable parts.

Importance of Regular Inspections

Ensuring that pump efficiency is upheld and avoiding breakdowns are crucial tasks that require regular inspections to be carried out diligently as per the API 610 standard, which underscores the significance of routine examinations in its guidelines, for preventive maintenance practices enabling early detection of possible concerns before they develop into significant issues.

Preventive Maintenance Guidelines

Ensuring maintenance is crucial in the API 610 standard as it offers comprehensive instructions for keeping pump systems in top condition efficiently. By adhering to these suggestions suggestions and tips operators can prolong the lifespan of their equipment. Reduce any potential operational interruptions. For instance For example companies such as Yantai Longgang Pump Industry Co., Ltd. which prioritize product quality with ISO9001;2008 certification and other quality system certifications demonstrate a commitment, to following these maintenance practices.

By understanding how the API 610 standard enhances pump performance through its comprehensive guidelines on design specifications, mechanical integrity assurance measures, regular inspections importance acknowledgment along with preventive maintenance guidance adherence—industry stakeholders can ensure reliable operations across various sectors ranging from petroleum refining processes down towards coal chemical applications among others served by trusted suppliers such as Yantai Longgang Pump Industry Co., Ltd., known for providing mature solutions tailored towards specific client needs globally!

Why is Compliance with API 610 Important for Safety?

Adherance to the API 610 standard plays a role in maintaining safety during pump operations.Its strict regulations aim to reduce risks and improve safety standards in industries, like petroleum, petrochemicals and natural gas where safety is paramount.

Safety Features Embedded in API 610 Standards

The API 610 standard includes safety elements crucial for the functioning of pumps, like durable bearings capable of withstanding tough operating environments and lasting a long time design wise These requirements guarantee that pumps can work reliably even in challenging situations minimizing the chances of mechanical breakdowns.

Moreover the dual suction impeller configuration found in pumps such, as the BB(LAD) series produced by Yantai Longgang aids in maintaining axial forces independently which leads to secure and steady operation of the system. By using this design approach it reduces pressure surges and vibrations thus improving the safety and stability of the entire pump system.

Risk Mitigation through Standardized Practices

Following the guidelines set forth in the API 610 standard is crucial in reducing risks, within the industry sector. Manufacturers who follow these guidelines can guarantee that their pumps meet safety requirements. This involves meeting the seal chamber size standards outlined in IS021049 (API682) which helps maintain proper sealing and prevents potential leaks that may result in dangerous scenarios.

Additionally highlighting the importance of checks and preemptive upkeep recommendations in line with the API 610 norm aids, in spotting possible issues early on before they snowball into significant concerns. This proactive stance notably cuts down on the dangers linked to pump functioning and guarantees a work setting.

What Are the Economic Benefits of Adhering to API 610?

Following the API 610 guideline has economic advantages for sectors that depend on pump systems thanks, to improved efficiency and lasting financial benefits associated with meeting this globally accepted standard.

Cost Efficiency through Enhanced Performance

Adhering to API 610 offers economic advantages by improving pump performance and achieving cost savings through enhanced efficiency and decreased energy consumption resulting from reduced cavitation margins, in pumps built to this standard.

Yantai Longgangs BB3 efficient centrifugal pump is an example of innovative technology in action with an impressive hydraulic optimum efficiency point of 90%. This surpasses the first level energy efficiency standard by 3% leading to substantial long term cost savings for users due, to its high performance levels.

Long-term Financial Advantages for Industries

Adherance to API 610 not offers immediate cost benefits but also brings long term financial advantages to various industries by ensuring the pumps are durable and reliable due, to their sturdy design and quality components specified in the standard.

By focusing efforts towards upkeep and guaranteeing the soundness of machinery systems in place before issues arise proactively can help enterprises sidestep pricey fixes and substitutions. This results in enhanced gains in the long haul, by limiting operational halts while keeping up productivity levels without facing extra costs.

How Does API 610 Influence Global Industry Practices?

API 610s impact is felt worldwide setting the standard, for industry practices across sectors that rely on centrifugal pumps transcending individual companies and regional boundaries.

Adoption of API 610 Standards Worldwide

The global embrace of API 610 standards on a scale highlights its importance in influencing industry norms in various parts of the world. Numerous nations regard these standards as yardsticks for ensuring quality because they offer instructions on design requirements and material selection criteria along, with testing protocols and more.

Yantai Longgang Pump Industry Co., Ltd. Is well known for manufacturing notch chemical centrifugal pumps that meet international standards like ISO9001;2008 certification and American Petroleum Institute (API) certifications. By adhering to recognized norms, such, as those outlined under the API 610 umbrella they have effectively expanded their presence in both local and international markets bolstering credibility and trust among customers worldwide.

Comparison with Other International Pump Standards

Comparing api6lo with international pump standards reveals significant differences, mainly in the depth and specificity of coverage provided. This makes the latter more comprehensive and exhaustive compared to the counterparts, in the market today.

In some setups the emphasis may be on specific areas of particular applications but api61 o covers a wider range considering various factors that impact performance, reliability and safety. This makes it the preferred option, for organizations looking to enhance operations and get the most out of their investments.