Industrial brake systems are the backbone of safety and performance in heavy-duty machinery, ensuring controlled motion, efficient stopping, and enhanced operational security. Whether you’re involved in manufacturing, mining, material handling, or any industrial application, understanding the various types of brake systems is crucial for both efficiency and safety.

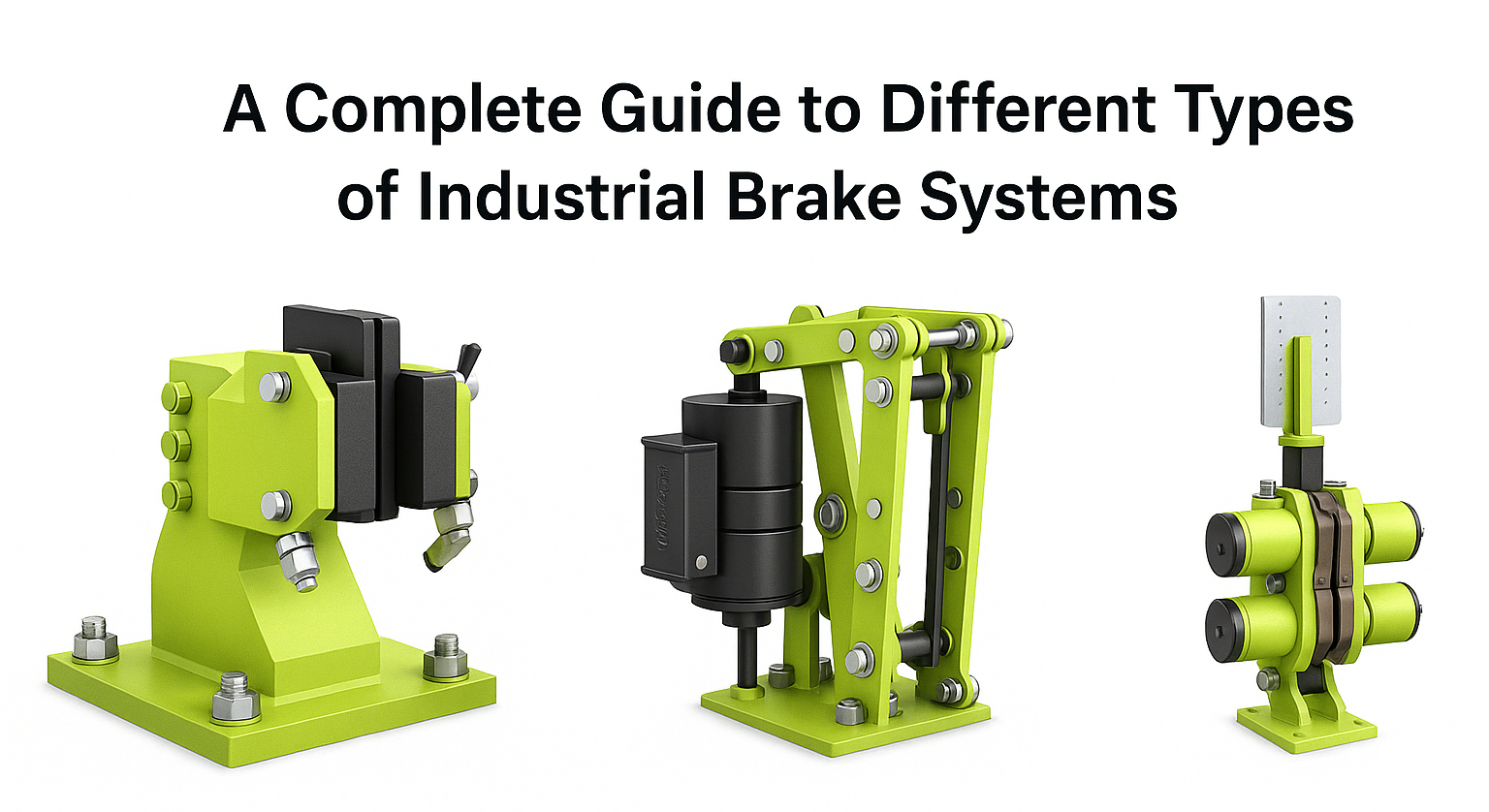

In this comprehensive guide, we delve into the different types of industrial brake systems—from industrial disc brakes to electromagnetic brakes in India, and thruster drum brakes—to help you make informed decisions for your machinery and equipment.

What Are Industrial Brake Systems?

Industrial brake systems are mechanical devices designed to slow down, hold, or stop the movement of machinery and equipment in industrial settings. Unlike automotive braking systems, industrial brakes operate under more demanding conditions—high loads, intense heat, and continuous operation.

These systems are vital for:

-

Machinery safety

-

Controlled motion

-

Emergency stopping

-

Load holding

1. Industrial Disc Brakes

Industrial disc brakes are widely used due to their high-performance stopping power and consistent operation under extreme conditions. These brakes work by applying friction through brake pads onto a rotating disc or rotor.

Key Features:

-

High thermal capacity

-

Fast response time

-

Easy maintenance

-

Suitable for high-speed applications

Applications: Conveyors, wind turbines, cranes, and hoists.

2. Electromagnetic Brakes

Electromagnetic brakes, also known as magnetic brakes, use electromagnetic force to apply friction. These brakes engage when electrical power is applied and disengage when it’s cut off.

Types:

-

Spring-applied brakes

-

Power-on brakes

Benefits:

-

No physical contact during operation (reduces wear)

-

Smooth and precise stopping

-

Quick actuation

Popular in India, electromagnetic brakes in India are seeing increased usage in automation and robotics due to their reliability and low maintenance.

3. Industrial Drum Brakes

Industrial drum brakes are one of the oldest yet most robust braking mechanisms. They consist of a drum that rotates with the wheel and brake shoes that press against the drum’s interior surface.

Features:

-

High torque capacity

-

Cost-effective

-

Versatile in application

They are often paired with thruster mechanisms, making thruster drum brakes highly effective in heavy-duty cranes and hoisting equipment.

4. Thruster Drum Brakes

A thruster drum brake uses a hydraulic or electro-hydraulic thruster to operate the brake mechanism. It provides a fail-safe design—spring-applied and thruster-released.

Benefits:

-

Auto-adjusting brake force

-

High reliability

-

Withstands harsh environmental conditions

Applications: Overhead cranes, material handling, mining equipment.

5. Hydraulic Disc Brakes

Hydraulic disc brakes utilize hydraulic pressure to apply the braking force. Known for their precision and strength, these brakes offer unmatched performance for large industrial machinery.

Key Advantages:

-

Uniform braking force

-

Minimal wear and tear

-

Excellent control at high loads

Common Uses: Construction machinery, wind turbines, and marine applications.

Choosing the Right Industrial Brake System

When selecting an industrial brake system, consider the following:

-

Load capacity

-

Speed of operation

-

Environmental conditions

-

Safety requirements

-

Maintenance frequency

Final Thoughts

Industrial brake systems are critical to the safe and efficient operation of any heavy-duty machinery. With a variety of options like industrial disc brakes, electromagnetic brakes, drum brakes, and hydraulic disc brakes, there’s a solution tailored to every industrial need. As automation and safety standards evolve, investing in the right braking technology not only enhances performance but also reduces long-term costs and risks.

FAQs:

1. What are industrial brakes?

Industrial brakes are devices that slow or stop machinery by applying friction. They are typically used in applications that require powerful and reliable braking systems, such as those found in mining, construction, and manufacturing equipment.

2. What are the three types of braking systems?

There are three main types of braking systems: electromagnetic, hydraulic, and mechanical.

3. Which braking system is best for Industrial applications?

Hydraulic braking systems are occasionally a good choice for industrial applications, especially for heavy-duty machinery.

4. What Is the Principle of the Brake System in Industrial Applications?

The basic concept of braking systems in industrial settings, like heavy machinery or transportation, is to use friction to convert kinetic energy into heat in order to slow down or stop a moving item.

5. What is an Electromagnetic Braking System?

An electromagnetic braking system uses friction created by magnetic force to slow or stop a moving object rather than relying on traditional mechanical friction.