When searching for the best oil roll on filling machine in UAE, it is crucial to know what constitutes a reliable, efficient, and suitable machine for your business. If you are establishing a new cosmetic production line or replacing your existing equipment, the right machine will determine the improvement in output as well as the quality of your products.

The following guide will assist you in determining the top factors to consider when purchasing an oil roll-on filling machine.

Know Your Product Needs

Before purchasing an oil roll-on filling machine, you must consider the type of oil you will be filling. Different oils have different viscosities, which can affect the filling process. Light essential oils, for instance, flow quickly and may not require a high-pressure filling system.

In contrast, thicker oils may need machines with stronger pumps and better control. Additionally, consider whether the oil contains any particles or fragrances that could clog the system.

Select Proper Bottle and Cap Sizes

Oil roll-on containers are mostly sold in small volumes of between 5ml and 15ml. Make sure the filling machine accommodates the precise bottle shapes and sizes you intend to use.

Also, confirm if the machine can accommodate roll-on lids and close them properly. Some models have variable nozzles or settings for convenience, which may be beneficial if your product line increases in the future.

Check Automation and Speed

The degree of automation in an oil roll on filling machine in UAE may range from semi-automatic to automated systems. If you are in a small business or just beginning, then a semi-automatic machine would be sufficient. But for mass production, an automated filling machine can save time and labour expenses.

You should consider the speed of the machine as well. A high-speed machine can yield more production, but ensure that it does not compromise filling precision.

Assess Machine Precision and Accuracy

Accurate filling is essential in providing uniform product volume and preventing wastage. The ideal oil roll-on filling machine must provide high precision, particularly for small-bottle sizes.

Seek machines that utilize digital control or sensors capable of controlling the precise volume of oil delivered to every bottle.

This assists in preserving product quality and customer satisfaction.

Material and Construction Quality

Since you are dealing with oils that could have natural or chemical ingredients, it is necessary that the filling machine is constructed using materials that are resistant to corrosion and contamination.

Stainless steel is a choice that is popular because it is strong and hygienic. Ensure that everything that comes into contact with the oil is safe and easy to clean. This will also enable you to adhere to health and safety regulations.

Ease of Use and Maintenance

A complex machine that requires constant technical attention can slow down your operations. Choose a machine that is easy to use with a simple interface and clear instructions. Additionally, maintenance should be hassle-free.

Machines with easy-to-remove parts or those that come with cleaning programs can save time and effort in the long run.

After-Sales Support and Warranty

Good customer support and a good warranty can make all the difference. Ensure that the supplier provides installation, training, and ongoing support.

Quick assistance and available spare parts are essential if the machine breaks down, to prevent extended downtimes. This is particularly crucial for companies working in high-speed environments.

Conclusion:

Selecting the correct oil roll on filling machine in UAE can have a significant influence on your production effectiveness, product quality, and company development. If you are filling perfume oils, essential oils, or cosmetic fluids, finding the correct machine which suits your specific needs is critical.

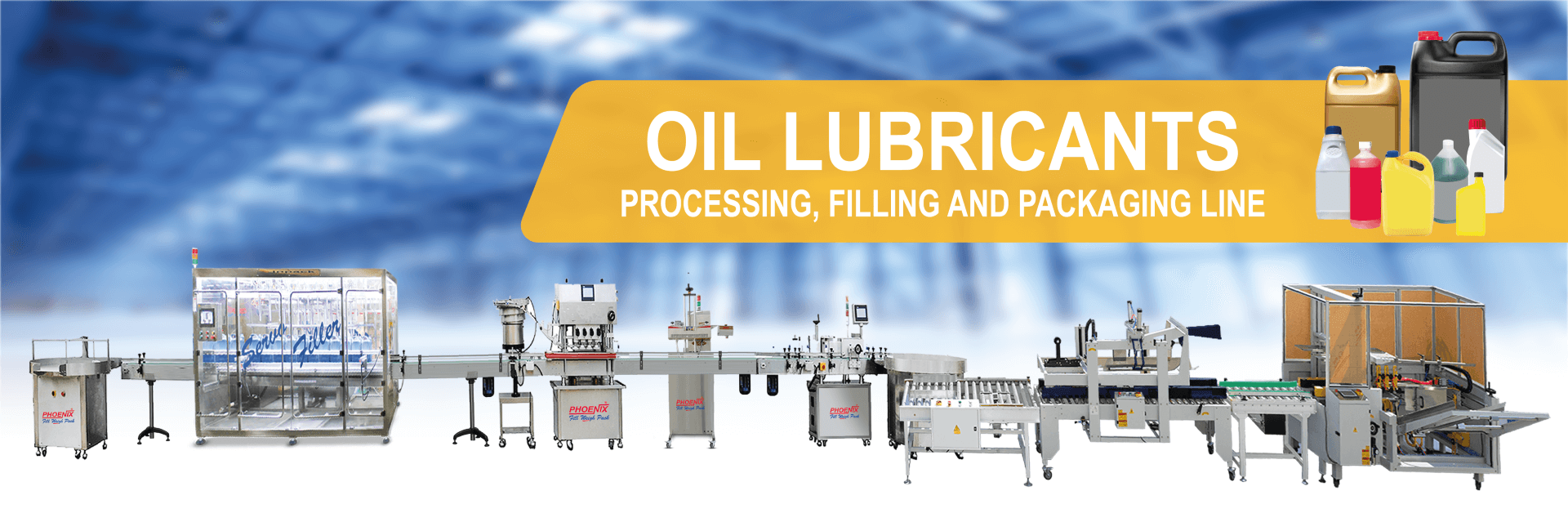

For high-quality solutions, Phoenix Dison Tec LLC provides high-quality and dependable oil roll-on filling machines ideal for companies in the UAE. Their skilled team offers good after-sales support, which makes them a reliable partner for your packaging requirements.