Enhancing Dental Restorations with Intraoral Scanning

Intraoral scanning technology has revolutionized the way dental restorations are created, providing dentists with a precise and efficient method to capture detailed images of a patient’s oral cavity. This technology eliminates the need for traditional impression materials, offering a more comfortable experience for patients and ensuring high accuracy in dental restorations.

Benefits of Intraoral Scanning

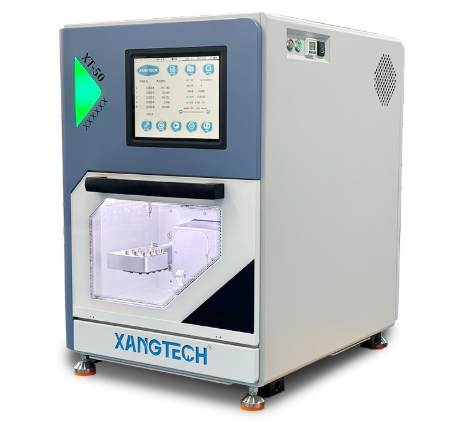

The primary benefits of intraoral scanning include increased accuracy, improved patient comfort, and enhanced communication between dental professionals and laboratories. By capturing highly detailed 3D images, intraoral scanners enable precise measurements that lead to better-fitting restorations. Additionally, digital files can be easily shared with dental labs like those using XANGTECH’s XT 50 milling machine, streamlining the workflow and reducing turnaround times.

Implementing In-Office Milling for Efficient Dentistry

This is an upgraded method and here the production of restorations is made in the dental clinics directly. Hence, it improves efficiency and patient satisfaction. Providing rapid and accurate prosthetics, the incorporation of machines such as the XANGTECH XT 50 allows clinics to create high-quality products directly. This allows clinics to produce high-quality restore materials within an acceptable frame and with maximum precision using machines such as the XANGTECH XT 50.

Same-Day Dentistry Solutions

Thanks to the XANGTECH XT 50’s perfect precision, clinics can fabricate crowns, bridges, and restorations within hours. This will not only cut the wait for patients in queues but also minimize the visits required to the hospital, boosting the patient experience a great deal.

Factors Influencing the Choice Between In-Office Milling and Lab Fabrication

When deciding between in-office milling and traditional lab fabrication, several factors must be considered to ensure optimal outcomes for patients.

Considerations Based on Location in Mouth

Furthermore, the positioning of the restoration within the mouth can affect the suitability of in-office milling compared to laboratory fabrication. XANGTECH’s 90-degree vertical cutting feature produces intricate finishes that replicate the texture of tooth enamel, making it ideally suited for anterior teeth where a higher aesthetic standard is required. This enamel-like texture, which is highly valued for anterior teeth restorations where minimal vertical wear is desired, can be effortlessly achieved with XANGTECH’s 90-degree vertical cutting capabilities.

Importance of Stump Shade in Restoration Choices

Choosing the right shade of stump is a must to resemble reality. Milling in-office means the aesthetic needs of patients can be adjusted mid-procedure based on their immediate feedback. This helps ensure that aesthetic requirements can be fulfilled quickly by making in-the-moment changes according to patient feedback.

Leveraging Digital Tools for Improved Practice Efficiency

In the contemporary dental landscape, leveraging digital tools is essential for enhancing practice efficiency and delivering superior patient care. Advanced technologies like intraoral scanning and dental milling machines are pivotal in this transformation.

Role of Intraoral Scanning in Modern Dentistry

Intraoral scanning is an important component of modern dentistry which provides an accurate means of acquiring high-resolution images of a patient’s oral cavity. The technology not only adds to the precision of accurate scans but also makes the process more comfortable by removing the need for traditional impression materials. This combination of high detail and 3D imaging means real measurements can help restorations fit precisely.

Cost Savings and Accuracy with Digital Impressions

One of the most significant contributors to developments in digital dentistry and ease of business is the affordability and accuracy delivered as a result of digital impressions. With the use of digital files, all information can be communicated to labs, including those with XANGTECH’s XT 50 milling machine. This combined capability lowers turnaround times, minimizes manual impression mistakes, and reduces costs while improving precision in restorations.

Crafting Handcrafted Crowns vs. Milled Crowns: A Comparative Analysis

The decision between handcrafted crowns and milled crowns involves several considerations, each offering distinct advantages depending on the specific requirements of the case.

|

Aspect |

Handcrafted Crowns |

Milled Crowns (XANGTECH) |

|

Precision |

Skilled craftsmanship offers a personalized fit |

High precision with consistent outcomes |

|

Turnaround Time |

Longer due to manual processes |

Faster with in-office milling capabilities |

|

Material Utilization |

Potential for material waste |

Optimized usage with C-type clamp |

|

Aesthetic Quality |

High aesthetic potential with skilled artisans |

Consistent quality with advanced milling features |

Advantages of Handcrafted Crowns by Elite Prosthetic Dentistry

The aesthetic quality of handcrafted crowns is second to none, especially in the hands of masters of prosthetic dentistry. These can be customized for individual patients to fit not only the specific size but even the specific proportions and colors of the other teeth. These crowns can be customized to suit individual requirements, thus providing a personal fit and appearance that is an exact match to natural teeth.

XANGTECH’s Contribution to Dental Milling Technology

XANGTECH has emerged as a leader in dental milling technology, providing innovative solutions that enhance the efficiency and quality of dental restorations.

Overview of XANGTECH’s Product Offerings

XANGTECH XT 50 milling machine represents top-notch technology built to cope with the challenges of contemporary dental laboratories. Features like automatic resume after interruption, 90-degree vertical cutting for finishing details, and a wide angular range on the B-Axis for complex implants give the XT 50 a boost in productivity and precision. The C-type clamp leads to the increased utilization of the material, minimizing wastage, and is also cost-effective when it comes to the material price.

With XANGTECH‘s technology integrated into their workflows, dental clinics become more efficient, reducing laboratory steps, and irreversible milling time and getting better restorations in a faster way. Such contributions highlight the difference that using dental mill technology can make to both clinical outcomes and patient satisfaction. The clinical examples presented highlight the changes in clinical outcomes that have been achieved by utilizing dental mill technology leading to enhanced levels of the patient experience and satisfaction.

https://www.dentalxangtech.com/